Are you ready to witness a groundbreaking transformation in the manufacturing industry? Look no further than lsr molding companies. These innovative companies are revolutionizing the way products are made, offering unparalleled precision and efficiency.

The Rise of LSR Molding Companies

LSR (Liquid Silicone Rubber) molding companies have emerged as key players in the manufacturing sector. With their cutting-edge technology and expertise, they have become pioneers in producing high-quality silicone-based products. From medical devices to automotive components, these companies cater to diverse industries with utmost precision and reliability.

One such notable player is JVTECH, a leading LSR molding company based in Delaware. With state-of-the-art facilities and a team of skilled professionals, JVTECH has gained recognition for its exceptional capabilities in producing intricate silicone parts that meet stringent quality standards.

The Remarkable Achievements of JVTECH

JVTECH’s commitment to excellence has earned them an esteemed reputation within the industry. Their advanced machinery allows for precise control over every aspect of production, ensuring consistent results that surpass customer expectations. Whether it’s creating complex geometries or achieving tight tolerances, JVTECH excels at delivering superior silicone solutions.

In addition to their technical prowess, JVTECH also prioritizes innovation and sustainability. They actively invest in research and development efforts to stay ahead of market trends while minimizing environmental impact through efficient resource management practices.

Unveiling 2K Molding: A Game-Changer

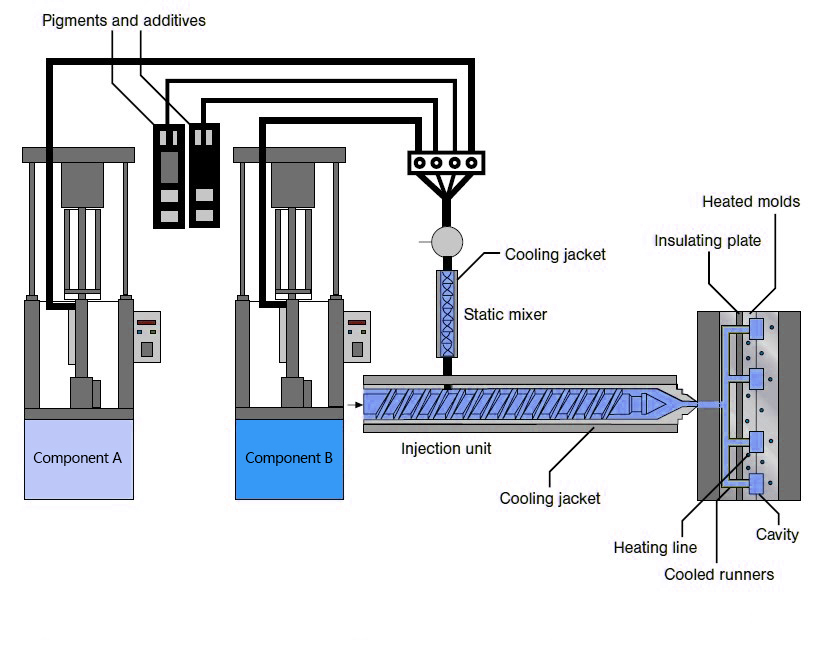

If you thought LSR molding was impressive on its own, let me introduce you to another game-changing technique – 2K molding. This revolutionary process combines two different materials into one seamless product using specialized injection molds.

With 2K molding, LSR molding companies like JVTECH can create products with enhanced functionality and aesthetics. By combining silicone with other materials such as thermoplastics or metals, they can achieve unique properties that were previously unattainable.

This innovative technique opens up a world of possibilities for various industries. From consumer electronics to automotive applications, the versatility of 2K molding allows for limitless design options and improved product performance.

The Future is Bright

In conclusion, LSR molding companies are reshaping the manufacturing landscape with their unparalleled precision and efficiency. Leading players like JVTECH in Delaware are at the forefront of this revolution, pushing boundaries and setting new industry standards.

Click what is 2k molding.As technology continues to advance, we can expect even more remarkable achievements from these companies. With their dedication to innovation and commitment to excellence, LSR molding companies will undoubtedly play a pivotal role in shaping the future of manufacturing.